Thermocouple Sheath Material

A thermocouple is often enclosed in a protective sheath to isolate it from the local atmosphere. This protective sheath drastically reduces the effects of corrosion.

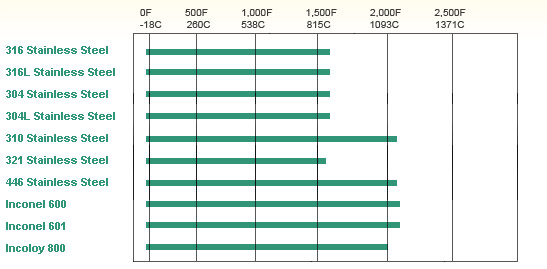

Specific Temperature Limits

316 Stainless Steel

- Maximum temperature: 1650°F(900°C). Best corrosion resistance of the austenitic stainless steel grades. Widely used in the food and chemical industry.

- Subject to damaging carbide precipitation in 900°F to 1600°F (482°C to 870°C).

316L Stainless Steel

- Maximum temperature: 1650°F (900°C). Same as 316 SST (04) except low carbon version allows for better welding and fabrication.

304 Stainless Steel

- Maximum temperature: 1650°F (900°C). Most widely used low temperature sheath material. Extensively used in food, beverage, chemical and other industries where corrosion resistance is required.

- Subject to damaging carbide precipitation in 900°F to 1600°F (480°C to 870°C) range. Lowest cost corrosion resistant sheath material available.

304L Stainless Steel

- Maximum temperature: 1650°F (900°C). Low carbon version of 304 SST (02). Low carbon content allows this material to be welded and heated in the 900°F to 1600°F (480°C to 870°C) range without damage to corrosion resistance.

310 Stainless Steel

- Maximum temperature: 2100°F (1150°C). Mechanical and corrosion resistance, similar to but better than 304 SS. Very good heat resistance.

- This alloy contains 25% chromium, 20% nickel. Not as ductile as 304 SS.

321 Stainless Steel

- Maximum temperature: 1600°F (870°C). Similar to 304 SS except titanium stabilized for intergranular corrosion.

- This alloy is designed to overcome susceptibility to carbon precipitation in the 900 to 1600°F (480 to 870°C) range. Used in aerospace and chemical applications.

446 Stainless Steel

- Maximum temperature: 2100°F (1150°C). Ferritic stainless steel which has good resistance to sulfurous atmospheres at high temperatures.

- Good corrosion resistance to nitric acid, sulfuric acid and most alkalies. 27% chromium content gives this alloy the highest heat resistance of any ferritic stainless steel.

Inconel 600

- Maximum temperature: 2150°F (1175°C). Most widely used thermocouple sheath material. Good high temperature strength, corrosion resistance, resistance to chloride-ion stress corrosion cracking and oxidation resistance to high temperatures.

- Do not use in sulfur bearing environments. Good in nitriding environments.

Inconel 601

- Maximum temperature: 2150°F (1175°C) continuous, 2300°F (1260°C) intermittent. Similar to Alloy 600 with the addition of aluminum for outstanding oxidation resistance. Designed for high temperature corrosion resistance.

- This material is good in carburizing environments, and has good creep rupture strength. Do not use in vacuum furnaces! Susceptible to intergranular attack by prolonged heating in 1000°F to 1400°F (540°C to 760°C) temperature range.

Incoloy 800

- Maximum temperature: 2000°F (1095°C). Widely used as heater sheath material. Minimal use in thermocouples. Superior to Alloy 600 in sulfur, cyanide salts and fused neutral salts.

- Susceptible to intergranular attack in some applications by exposure to the temperature range of 1000°F to 1400°F (540°C to 760°C).