Reotemp offers a variety of RTD assemblies for use in industrial, oil, gas, refining, power generation, biotech, pharmaceutical, food and beverage markets. From standard RTDs to high accuracy RTDs, Reotemp offers a multitude of products for a variety of diverse applications. For high vibration applications Reotemp offers the unique Hi-Vibe™ option which reinforces the RTD and dramatically extends the life of the sensor in high vibration applications.

What is an RTD?

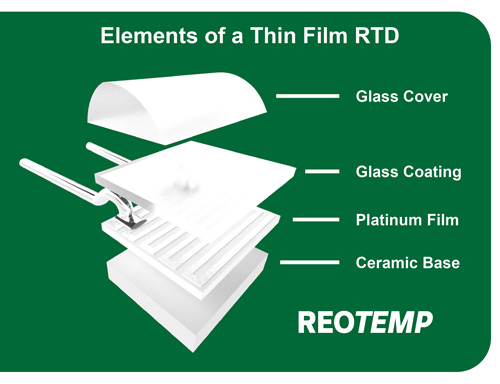

An RTD (Resistance Temperature Detector) is a temperature sensor that uses electrical resistance to indicate temperature. Certain metals display a characteristic and well-defined change in electrical resistance that corresponds to a change in temperature. By measuring the resistance of a known metal, the temperature can be calculated based on known response curves. RTDs are manufactured by placing a precise amount of metal onto a ceramic base in a thin film or wound wire format. By passing a small, precise current, typically 1mA, through the RTD and measuring the corresponding resistance, the temperature can be calculated.

Types of RTDs

RTD’s are categorized into different groups based on the resistivity of the metal used inside. Most modern industrial RTD’s use platinum as the resistive metal due to its inherent stability, temperature range and regularity of its temperature curve. Reotemp also offers less common RTD types such as nickel or copper to match and replace legacy and niche sensors.

| RTD TOLERANCE CLASSES | |||

|---|---|---|---|

| Tolerance Class | Operating Range °C | Tolerance Range °C | Tolerance Values °C |

| B | -200 to +600 | -200 to +600 | ± (0.3 + 0.005 | t | ) |

| A | -200 to +600 | -30 to +300* | ± (0.15 + 0.002 | t | ) |

| AA | -200 to +600 | 0 to +150* | ± (0.1 + 0.0017 | t | ) |

| 1/10 B | -200 to +600 | 0 to +50* | ± (0.03 + 0.0005 | t | ) |

| *Class B tolerance for rest of operating range. | |||

Platinum RTDs are offered with various classes/accuracy tolerance values. These classes are specified in IEC 60751 and ASTM E1137. Please see the RTD Tolerance Classes table on this page for the typical platinum RTD tolerance classes.

RTD Accuracy – Comparing Class A, B, AA, and 1/10B

A common misconception is that RTD accuracies are a fixed percentage across the board. This is not true. The accuracy of an RTD varies with temperature. To find the accuracy of an RTD, a formula is used to calculate the accuracy at a specific temperature point. Reotemp offers platinum RTDs that conform to internationally recognized classes. For each class, a different formula is used to calculate the accuracy at the specified temperature. These standards specify the accuracy formulas for an industrial platinum RTD. For customers who require a higher accuracy than offered in the B, A or AA classes, Reotemp offers 1/10 B RTDs. 1/10 B RTDs are 10 times more accurate than class B RTDs.

| ACCURACY COMPARISON: CLASS A VS B | ||

|---|---|---|

| Temperature °C | Class A RTD °C | Class B RTD °C |

| -190 | 1.25 | 1.25 |

| -100 | 0.80 | 0.80 |

| -50 | 0.55 | 0.55 |

| 0 | 0.15 | 0.30 |

| 50 | 0.25 | 0.55 |

| 100 | 0.35 | 0.80 |

| 200 | 0.55 | 1.30 |

| 300 | 0.75 | 1.80 |

| 500 | 2.80 | 2.80 |

Comparing RTDs with Thermocouples

The primary reason RTDs are chosen over thermocouples is their superior accuracy.

RTD vs. Thermocouple – Range, Accuracy, Durability, Response Time

Two of the most common methods of electrical temperature measurement are Resistance Temperature Detectors (RTDs) and Thermocouples. This video summarizes some of the differences in temperature range, accuracy, durability, and response time between RTDs and Thermocouples.

| ACCURACY COMPARISON: THERMOCOUPLE VS RTD | ||

|---|---|---|

| Type K Thermocouple | Class B RTD | |

| 32°F (0°C) | ± 3.96°F (2.2°C) | ± 0.54°F (0.3°C) |

| 392°F (200°C) | ± 3.96°F (2.2°C) | ± 2.34°F (1.3°C) |

- RTDs offer better stability with less temperature drift over time as they age versus thermocouples. Less temperature drift results in a longer service life and more accurate data.

- RTDs are also a better choice for low temperature applications as they have much better accuracies below 0°C. At temperatures below 0°C, thermocouples are less stable and less reliable.

- RTDs offer better repeatability. When temperature moves from a point and then returns, RTDs return much closer to the original point.

- RTDs offer greater interchangeability. When replacing or swapping sensors, the match between each sensor is much closer.

- In cases where long lead wires are required, RTDs are often recommended. This is because thermocouples require a more expensive lead wire consisting of the same metal as the thermocouple sensor. With RTDs, only common copper hook up wire is needed.

Operating Temperature Range

Reotemp RTDs are typically offered in two versions of operating temperature ranges. The chart below shows the operating ranges of standard and extended temperature RTDs. Choose the extended temperature option when the application requires high temperature exposure.

| RTD TEMPERATURE LIMITS | ||

|---|---|---|

| RTD Type | Minimum Limit | Maximum Limit |

| Reotemp Standard RTD Range | -328°F (-200°C) | 400°F (204°C) |

| Reotemp Extended Temp |

-328°F (-200°C) | 1112°F (600°C) |

RTD Failure Modes Explained

RTDs are extremely reliable temperature sensors. However, when they do fail, the failure modes can be typically broken down into the following categories:

Excessive Temperature

When RTDs exceed their designed temperature limits, the wire insulation materials in the stem will start to break down. This can result in electrical shorts and resistance errors. It can also create pinholes in the stem and cracks in the potting sealing the stem. When the stem integrity is breached, moisture can then get in and cause resistance errors.

Corrosion

Corrosion will often result in pinholes and pits in the stem. Once the stem is no longer sealed, moisture and the process can penetrate the stem causing resistance errors and electrical shorts. Some solutions to corrosion include thermowells or Teflon coated stems.

Extreme Vibration

Extreme vibration fatigues and strains wires and welded connections inside the sensor assembly. This can result in resistance errors as well as connection breaks. Reotemp’s solution to this failure mode is the unique Hi-Vibe™ option for vibration applications.

User Abuse

Some examples of user abuse include wires shorted out from being twisted together or corrosive media being allowed into the RTD assembly head.

Wire Configurations of RTDs

2 wire, 3 wire and 4 wire RTD Explained

A Resistance Temperature Detector (RTD) is a temperature measurement device that accurately uses resistance to measure temperature. Learn the differences between 2-wire, 3-wire, and 4-wire RTD’s and which one you should choose for your measurement needs.

2-Wire

2-wire configurations are the most basic, and offer no lead wire compensation. This means that the resistance of the lead wire is added to the resistance of the RTD element which makes the measured temperature appear higher than the actual temperature. While the influence of lead wire resistance is minimal for short runs, longer lead wire results in a higher discrepancy.

3-Wire

A 3-wire configuration uses the third wire to sample lead wire resistance and subtract it from the measurement circuit. This is the most common configuration for industrial applications and provides adequate compensation for lead wire resistance.

4-Wire

A 4-wire configuration fully isolates the resistance of the RTD element from the resistance of the lead wire and is recommended for applications requiring the highest accuracy.

What’s the maximum lead wire length for a thermocouple or RTD?

How long can RTD lead wire be? How long can thermocouple lead wire be? What about 4-20mA transmitter lead wire? Find out in this video.

RTD Response Time

The diameter of the RTD probe will affect the response time of an RTD, as shown in the RTD Typical Response Times chart on this page. If response time is critical, consider using the smallest diameter probe which still meets the application requirements.